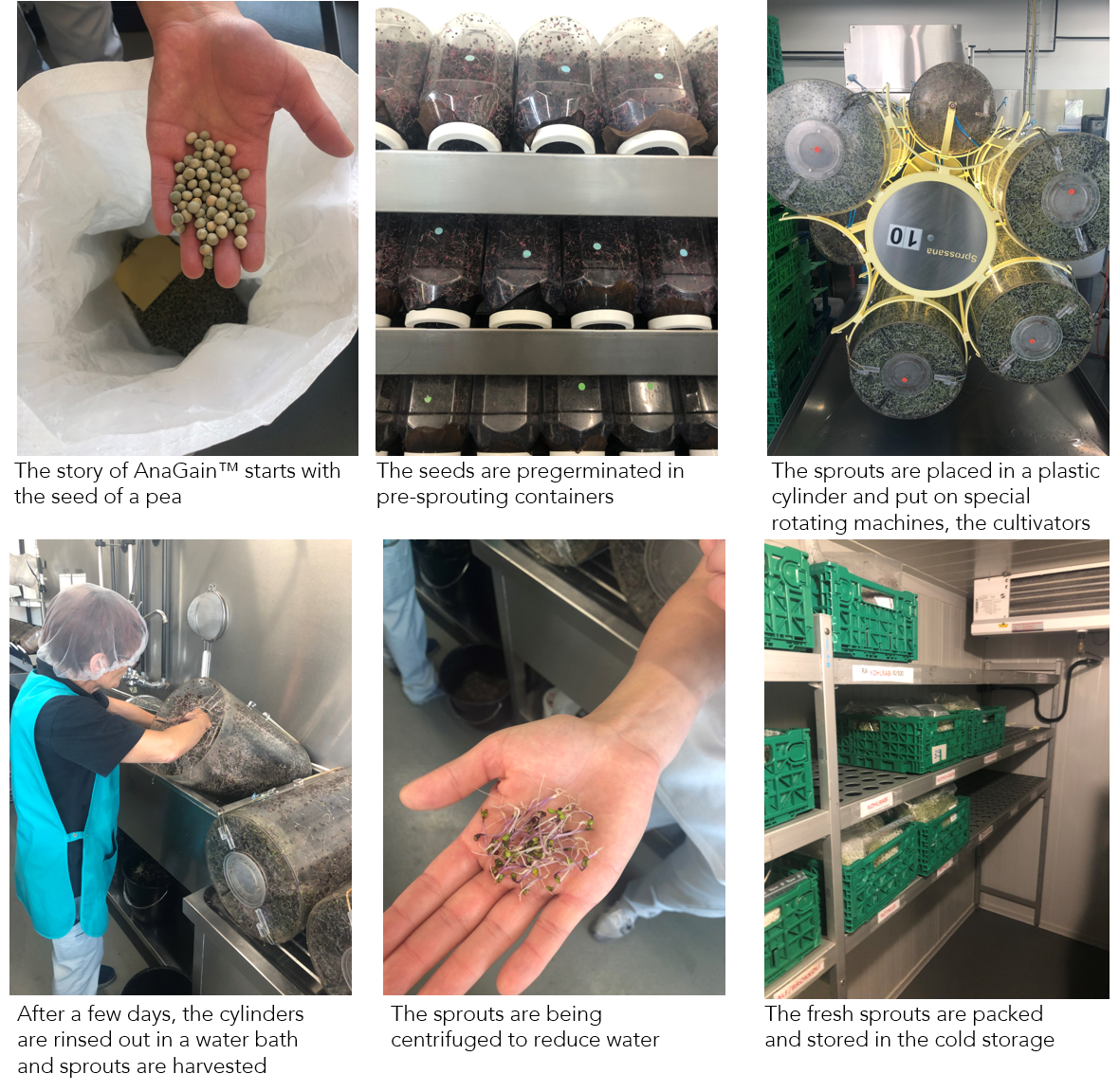

Behind the scenes: The story of AnaGain™

Where do the pea sprouts for our active ingredient AnaGain™ come from?

A trip to a small village in the canton of Thurgau.

The history of Sprossana began 15 years ago, when Mrs. Wartenweiler began to cultivate sprouts in her own apartment. The original thought behind it was the health aspect, since sprouts have a very high vital substance content. Today Sprossana is a family owned business with 10 employees. The specialization lies on the dynamic cultivation of different types of shoots. In intensive manual work, over 20 different sprout varieties are cultivated by the company 7 days a week. The customers are vegetable traders, the gastronomy, the retail trade and bakeries.

The story of AnaGain™ starts with the seed of a pea. At Sprossana, all shoots, including our pea, are first soaked in water overnight. This already starts the germination process. The seeds are then pregerminated in pre-sprouting containers in order to achieve an optimum result. Our pea is rather "fast", other seedlings such as beetroot need significantly longer time until they reach the next production step.

The pre-germ containers are turned four times a day to ensure that the seedlings are exposed to an even supply of light, and that oxygen can penetrate optimally. This also counteracts unwanted rot. When the pregerminated sprouts have reached the desired length, they are placed in a plastic cylinder. On special machines, called cultivators, the cylinders find their place and are rotated in a predetermined rhythm, irradiated with light and sprayed with water. Apart from water, air, light and love, the sprouts don’t need anything to grow. The constant rotation is very important, to ensure all seedlings receive enough light, allowing the sprouts to develop evenly.

The time on the cultivator varies depending on the type of shoots, it can range from two to four days. Afterwards, the shoots are harvested, which means the cylinders are rinsed out in a water bath. In order to avoid losses of vital substances, this has to happen quite fast. For all other shoots exept peas, the brown pods are now being removed. This increases shelf life and makes the sprouts look more appealing.

In the next step, the sprouts are centrifuged in order to keep the amount of water as low as possible and thus extend the shelf life. Then the fresh sprouts are packed and stored in the cold storage. A short drive later, they arrive at Mibelle Biochemistry, where our production department is already waiting to process the valuable sprouts into our active ingredient.

Stay tuned to find out how the shoot becomes the active ingredient AnaGain™!